Vertical Rotary Planetary (VRP)

Why VRP?

Accurate and repeatable precision spray processing can only be achieved by uniformly exposing the surface of the workpiece to a controlled flow of fluid for a specific period of time. Simply exposing the workpiece to a pressurized fluid spray will invariably produce uneven results due to such common conditions as puddling, tear-dropping and nozzle-patterning. Standard vertical spray technicians, even rotation, wont eliminate these problems – IPS, Inc VRP does!

There are five Dynamil VRP precision chemical spray processing machines for every experimental prototype or production of wet impingement recruitment. By precision, we mean consistent tolerances of less than 1 mil apart.

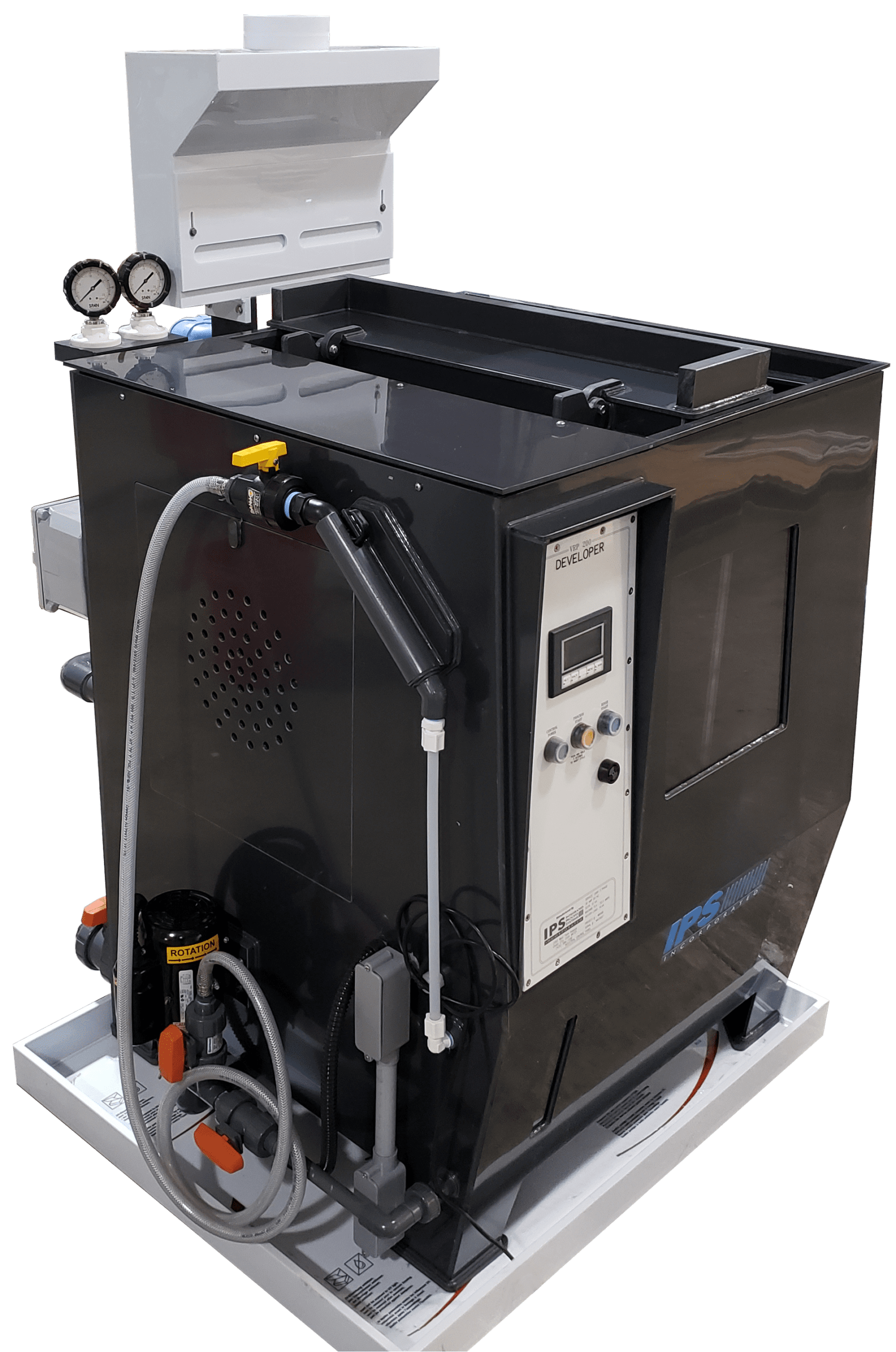

The secret to this accuracy is VRP – Vertical Rotary Planetary – a new patented method of chemical spraying that insures uniform processing and tight tolerances by eliminating common variables mentioned above. The VRP method works the piece vertically, rotated in a planetary motion- a continuous process that prevents a given point (substrate) from being worked again. Each VRP model is custom engineered using thermoplastics and/or metal, depending on your needs. The VRP is suitable for designated application and has only two moving parts. The VRP mechanism and the IPS, Inc centrifugal pump.

Other standards features include, built-in light and rinse tank, circulating water bath, solid state digital temperature control, automatic resetting times, and complete instrumentation to control the wet spray process. Contact our sales team at sales@ips-vcm.com or call 435-586-1188.